A small front lamp could be made due to make in common system of front and tail lamp. In case of that battery and circuit would be mounted to the tail lamp. Front, around handle, is desired to be neat and clean especially for a roadbike or a sport typed bicycle.

There are many merits due to use the battery and the circuit in common. I had wished to use a security alarm in common though I couldn't find a good shell for it inmounted to a saddle.

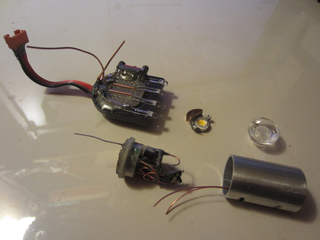

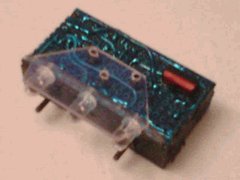

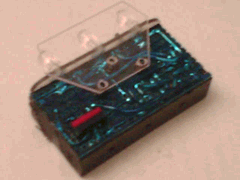

As for a left picture there are parts of a head lamp. It would be most small class one in guessing. The battery and the cicuit would be installed to the unit inmounted to a saddle.

Of course bombshell LEDs could be inmounted to an atatchment or a holder though there is not reason to make so small.

Demerit of that is the cable which should be brought out and be splined in top tube.

Bombshell LEDs could be inmounted to any parts even if it's small part, e.g. a mounter of cycle computer, any belt, a brackets, and so on.

It's might be good to affix a plate mounted high performance LEDs to around head, to make an atatchment for bombshells, and so on.

At the end of consideration, --

I made an atatchment to be mounted to bottom of the belt of a cycle computer. It would be possible to take off and be in the shade. Around the head would be clean too. As for the atatchment, it was already made for another mono-head lamp.

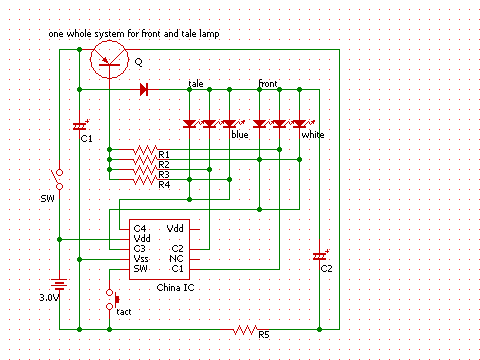

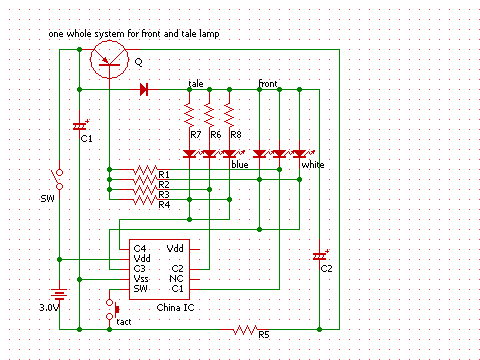

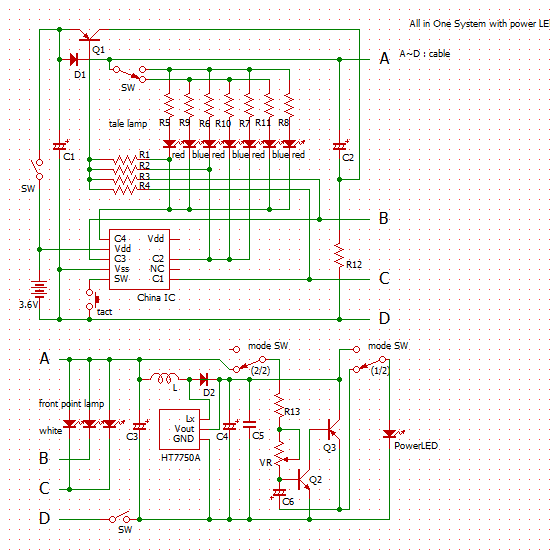

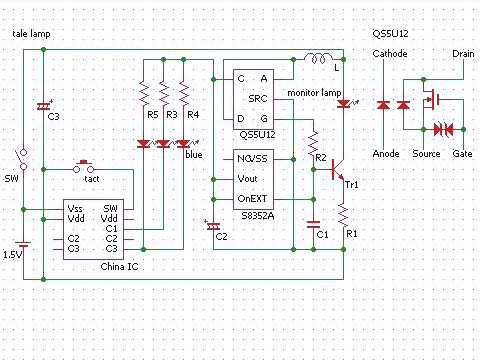

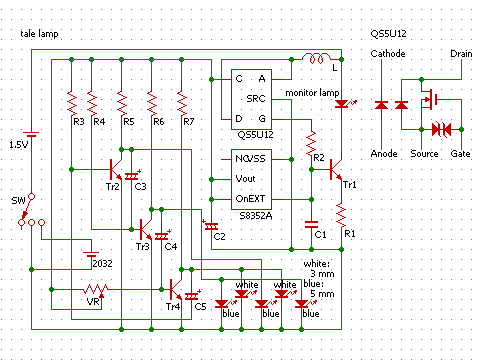

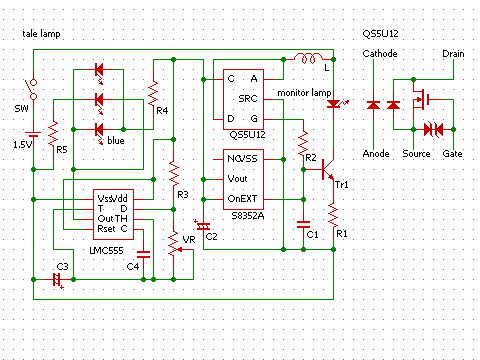

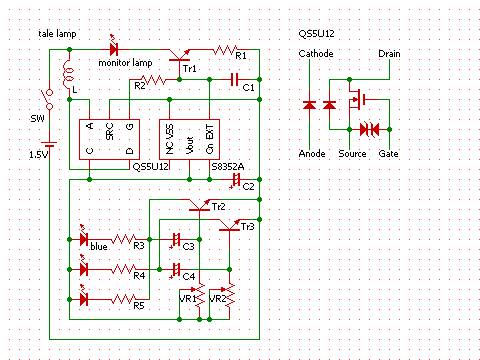

There is a right IC to be diverted which is made in China, and has seven patterns of flash, is used for a cheap tail lamp and toys.

There are two types as old and new. New one has four control lines which is convenience to divide to front and tail. Old one has three control lines in which case it's good to use one line in common of front and tail.

Old and new chips have same count of pins. Old chip has five pins for three control lines, new one has four pins for four control lines and has one NC pin. New one come to stand higher voltage than old one.

Its basement come to be used better material.

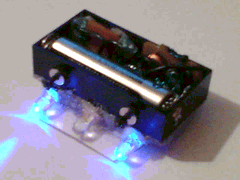

Cut its basement with enough margin as a right picture. It could be cut more small for installation.

As for the IC, I wrote a chaptor named

"divert IC flashing by Open Collector" in depth

Divides control lines to front and rear.

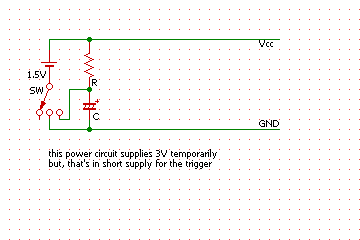

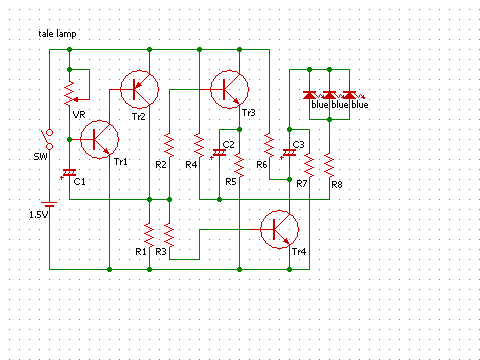

It's aim to charge pump due to oscillation without dcdc circuit, which could turn on lighting white and blue LEDs by two NiMH cells.

Focal points as follows:

- charge pump due to oscillation

- turn on/off due to one motion of a switch

- fixed flash pattern selected

- prevention momentary power off

Cause one flash time is very short by the IC, resistors as current limiter are no need. Its efficiency would be good in guessing.

It might be better to use resistors for blue LEDs. It's a matter of taste though a blue LED has high visibly respect to illumination.

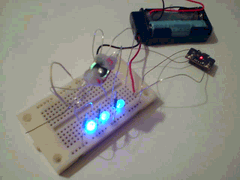

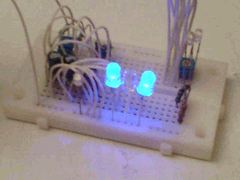

As usual, tested on a breadboard. At first I used a dcdc though, which could not flash as expected. It could not turn off completely. I did investigation of cause, but I couldn't find it.

And I decided to adopt the charge pump method.

As a matter of fact, at the outset I had an intention to use a dcdc cause that's easy and simply. And I changed the plan to design the charge pump used oscillation. Thus I couldn't test the circuit on a breadboard well.

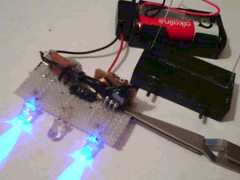

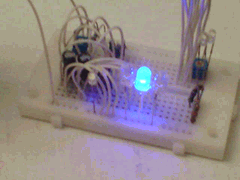

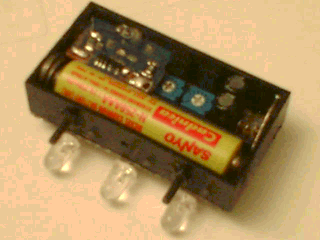

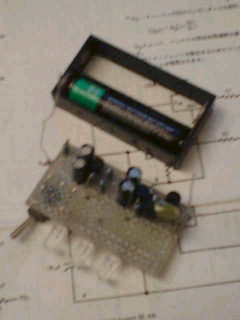

On a basement checked.

Cut the basement kinda larger than battery box and mounted some parts on it.

It needs a cable with three wires and put a connector on it. Three wires are for Vdd and two collector control lines.

It could be used as mono-tail lamp without cable to the front lamp.

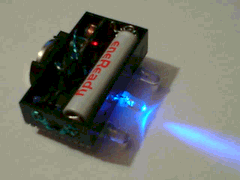

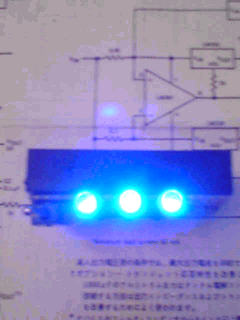

Heaped LEDs of a front lamp. It's interesting that the flash lighting is moving ups and downs.

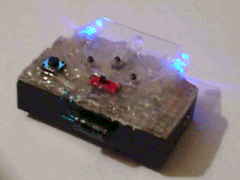

Set the front lamp as a right picture.

The light set to an atatchment mounted on bottom of a holder of a cycle computer. That's small and in shade.

As for an acrylic dome, it has visibly for side angle lower illumination though.

A tail lamp inmounted to a saddle.

Flashing due to momentary lighting is so pretty.

this way. Installed resistors for blue LEDs of a tail lamp.

A blue LED is easy to secure visibly respect to its illumination.

Resistors as current limiter of a tail lamp would make electric power margin for a head lamp, cause charge pump due to oscillation. That's efficiency in guessing.

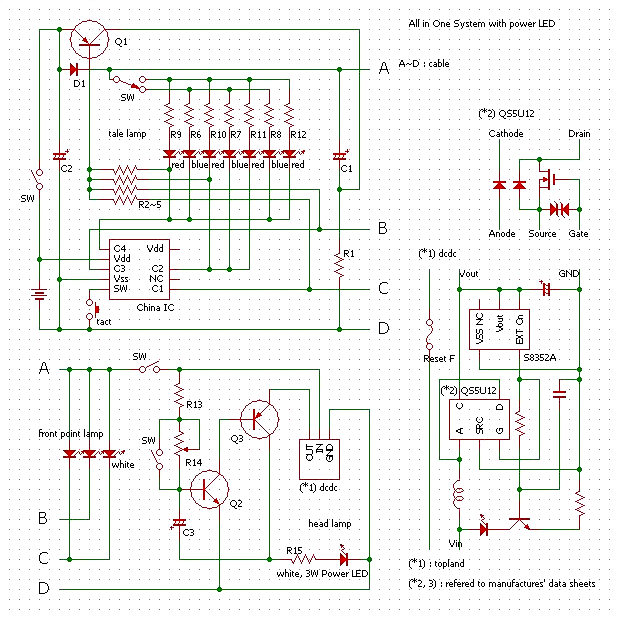

This circuit drew after adding a Power LED for front and adding red bombshell LEDs to rear before exchanging count of cells to three.

Blue LEDs of a tail lamp had come to turn off during the Power LED of head lamp was lighting constant. That's voltage droped down. Added four red LEDs to tail lamp which could be exchanged by switch, which didn't turn off while a Power LED was lighting constant cause red LED's Vf was lower.

As for a right picture, three white bombshell LEDs were inmounted to the atatchment before a part of a Power LED mounted on it.

Increased count of cells to three which made blue LEDs not turn off while a Power LED was lighting constant.

This is a part of a tail lamp inmounted to a saddle.

Exchanged the battery box for two AAA cells to one for three AAA cells.

It would be located over side of LEDs.

Blue LEDs didn't turn off while a Power LED was lighting constant.

I wondered when the battery dropped down it's not so wrong cause constant lighting of a Power LED is used rarely.

One flash lighting had come to be long due to change the voltage of battery. Illumination is enough but it had been impossible to flash quickly and that made runtime short.

That could be adjusted due to exchange a condenser or resistors though which had been left.

Expected to be high efficiency, high illuminative and momentary one flash due to three cells 3.6V.

There is no constant current circuit nor resistor as a current limiter.

Puts the output of a dcdc into a Power LED directly. HT7750A boosts 3.6V of battery to 5.0V. The current is limitted by the indactance. That might be a wrong method though it had worked well. Maybe good efficiency?

Old part for bombshell LEDs is used an atatchment of an adaptor as same as before. There are four LEDs diameter 3mm. A recent high performance LED is very luminous.

I didn't draw on the diagram though, added a switch with 2 circuits 2 positions which could shift a Power LED and bombshell LEDs due to one motion.

It's possible to turn on both of them due to shift to bombshell side and turn on the own switch of a Power LED.

It's ideal to tun on the warning lamp though that would be need many parts. Simply I added a small red monitor lamp which would be turned off to reached proper final voltage of NiMH battery.

Voltage dropped is depends on value of load, adjusted to be standardized constant lighting of a Power LED.

Concretely, connected a zenner diode and a resistor, a red LED in series among Vdd and GND. Several mA current is enough for that.