What could it use for a power source?

It's dangerous to use AC source for home use, and that's needed a trans and a bridge which are relatively large parts, and it would be difficult to inmount them to the spin brush and it would be heavy. With that, it's better to use an AC adaptor for its weight.

An appropriate one of AC adaptors on desk use could be used, which has voltages around 12 ~ 5V, that's enough for a power source of the spin grinder.

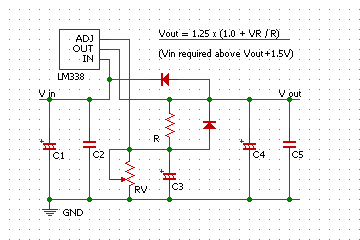

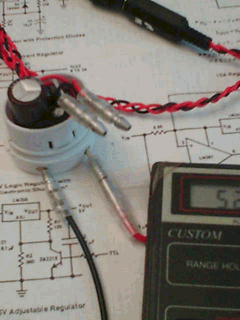

A variable voltage power supply has wide allowable range.

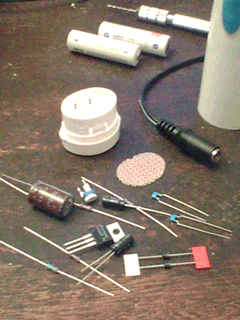

As for a variable voltage power supply used three terminal regulator, it could used LM338, 335, 317, which could lead 5.0A, 3.0A, 1.5A in order, which all are enough.

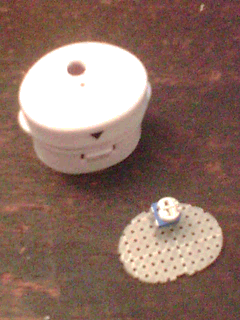

The circuit would be inmounted to the cap for exchange batteries.

I used 1000uF for C1 condenser side of V-in, which could be allowed for power source which is not so smooth. Case with a trans and a bridge, it would be more large capacity.

As a diode, it might be no need though, for prevent spike current.

Voltage for output would be determined by R and VR, which range is 1.25V ~ 9.2V as theory value which upper value is Vin - 1.5V.

A hole of the cap bottom is let into driver which could control the output voltage.

It's better to use VR as encapsulated type though.

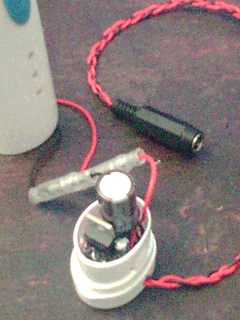

I thought it's easy to exchange the motor due to be inmounted all of circuit to the cap. The motor would be heat slightly after endurance test one hour running with 8.0V.

kinda density.

There is no space for mounting a jack connector, which was pulled out with a connector wired.

If there were large difference in potential between V-in and V-out the regulator would have a fever and need a cooling body.

In use few voltage as difference in potential, a cooling body might be no need.

I would make holes on the shell as exhaust heat holes.

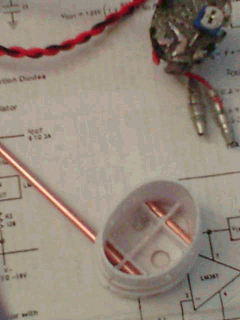

As a variable voltage power supply, I made an external output terminals.

Two copper pipes were mounted as terminals for output which inner diameter was 2mm as a standard pin terminal.

However,

make it this far,

It was better to make a general purposed variable voltage power supply, separately from the spin grinder, and use it for power supply for the spin grinder and others.

what's ideal?

variable voltage as 1.25V ~ 24.0V.

with a voltmeter and an ammeter.

power source as AC powered for home use with a trans and a bridge, large capacity condenser.

A bird cries too late when it is taken.

with cooling body for the regulator.

Finished