It's natural that a wheel is attached a high value. In that case, aerodynamics and weight are especially attract a great deal of interest which effect upon the high speed performance and the acceleration, hillclimb as continuous acceleration.

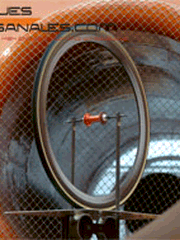

As a high speed performance, an important consideration is the aerodynamics. Results of wind tunnel experience under 50km/h was released on a publication. 50km/h is the velocity on professional time trial race. For that region, rim height and spoke count, shape of spoke bring differences.

A front wheel with the classic rim and 32 spokes requires 50 ~ 60 watts as load power for the velocity 50km/h under standard air density though, a recent mostly aero wheel requires 20 ~ 30 watts under same circumstances, which difference would be around 30 watts. Absolutely for the velocity 50km/h.

And the dynamic balance is important, a wrong wheel as that would bring oscillation over around 40km/h which increases rolling resistance and loss of torque.

It's natural to select high accuracy wheels for the time trial race.

However, as today's wheel, classic rim is none. As a hand built wheel, it consists of semi-aero rim 20 ~ 30mm height which load power is around 35 watts for the 50km/h. It differs only 15 watts compared to a highend aero wheel for the 50km/h.

This difference decreases dramatically for lower velocity range. It's several watts for 40km/h as an example.

How important 10 watts difference is?

For the 50km/h, even an earo bike requires 400 ~ 450 watts thrust power, a roadbike with under handle position requires 500+ watts, a roadbike with another position requires 600 watts above, any bike with casual wears requires 700 watts above.

Of course, slight difference would be important for race though. Are there other important factors?

As for hillclimb, aerodynamics is worthless, lightweight is none other than the worth. With that, a classical rim with 28 holes was once hailed, and an idiot physical estimation "wheel weight effects dozen fold" had sympathy.

Recently manufactures publishes the inertia moments of wheels. It's possible to get the equivalent mass due to divide it by a radius of the wheel. Practically, additional weight as equivalent mass is around 50%. i.e. wheel weight saving 100g is worth to weight saving 150g. Diet 1kg has more effective worth, which is not kidding but a truth.

Around here, about the power load,

there is a calculator software named "cyclePowerSim" which could simulate the cycling power due to set a rider's body and equipments specifications, various environments.

Especially about wheels, it coulld predict the aerodynamics due to rim-height and spoke counts, which calculates non-linear processing due to results of wind-tunnel measurement of dozens high-end wheels.

What factors the wheel has for its performance?

- aerodynamics

- dynamic balance

- weight, inertia moment

- torque efficiency

- rotational distortion, lateral stiffness

- endurance

Already mentioned, for the TT race, the first two factors should be counted.

What's important? as for general road race, that depends on the strategy or athlete type, course condition and so on. That might be same as TT race in case of escaping which is rarely succeeded though.

As for the last sprint, weight and inertia moment, torque efficiency are important. Aerodynamics might not be so worth due to utilize the peloton during cruising, acceleration become to be worth around high speed range.

As for criterium, lateral stiffness is worth too for cornering. A wheel dedicated to aerodynamics is easy to deflect generally which would make the understeer. That's could not be so-called "rear is fast". And, acceleration performance is important as same as the sprint.

Ease of maintenance couldn't be called performance but is worth for touring as an example. If one spoke was broken it's possible to go an area shop, and to exchange it easily. All depend on endurance and ease of maintenance for touring.

As rough directions, manufactures wheels are going to delicate to high speed performance, hand built wheels are not going to delicate to something but have a possibility to get various performances balanced due to compatibility. That changes depending on elements.

Without questions, manufactures aero wheels should be selected for the TT race, hand built wheels should be selected for touring. And, for the criterium, it might be selectable to apply hand built wheels which are lightweight and high stiffness.