It's better to check Psion due to PsiWin before decompose -- is it really flexi broken?

It can be checked no better than to look over the mother board and the keyboard. That's done due to look files in Psion due to PsiWin on Windows. If the Psion kept cable setting with battery it's able to do as it stands. However the Psion in first boot due to insert battery is set infrated connection the setting should be changed without LCD.

in case procedure for Psion is follow as

-- insert battery

-- connect cable

-- push ESC Key at once (boot Psion)

-- push MENU Key at once (pulldown the Menu)

-- push Left Arrow Key at once (select Tools)

-- push Under Arrow Key twice (select Remote link)

-- push ENTER Key at once

-- push Left Arrow Key at once (select Cable)

-- push ENTER Key at once

This procedure would make Psion to be able to connect with PsiWin on personal computer. If not there is not defective of flexi but defective of other parts.

Get off three bolts located in cover of battery cell and located in holder of CR2032, located in insertion of stylus.

Get off back shell.

Pull out back cover with battery cover.

Get off three bolts fixing mother board.

Pull off connector of electronic buzzer.

The mother board could be floated, but still connected with keyboard and LCD due to flexi cables.

Open LCD partly which makes the board to float more.

It's easy to do it with Psion drawn up, and pull out flexi cables of keyboard and LCD.

Mother board would be off.

Get off arms which fixes shell of LCD to frame.

-------- it's easy to understand without images as follows --------

Pull out two pins which fixes shell of LCD and keyboard.

Pull out keyboard due to slide on frame.

Get off shell of LCD and pull out LCD, get off cover and back lid.

Check flexi at this phase.

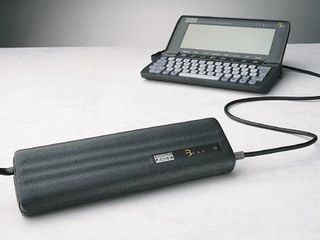

Connect mother board and LCD, keyboard and boot Psion with AC adaptor. And try to bend the flexi which is expected to display normally.

That's probable to make useless effort in case bad breaking of wire ...

LCD displayed normally due to just pinch lines side of the hole by pincette.

I understand to try to repair the flexi with fitting wire considering labor hour for exchanging the flexi though, it's same as to have a time bomb isn't it? ...

try to use stylus normally.

This method for check should be done after exchanging the flexi.

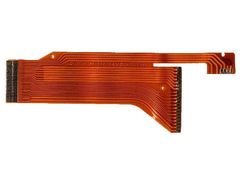

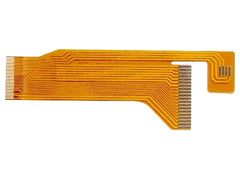

I compared the new flexi to the original flexi after get off the original flexi broken and so I found part of connection to LCD side of the new flexi is longer than the original flexi. I wonder it's to be cut off or to be fold back though, well it's okay whichever.

Attention not to strip off the lands of LCD side when the original flexi is got off. The land is weak for over heat and tensility, and it's difficult to repair in case strip off.

It should be done to mop up the solder as possible and not to compel flexi to strip, to get off with proper heat.

-- especially never strip with short heat.

After the flexi was got off it's important to check there are measurable solder on the land. If solder is too few it's difficult to do soldering. If solder is too much it's easy to be bridge-short.

Put solder on connection part of LCD side of new flexi.

After soldering new flexi to LCD, check all connection by testor, or it might be good checking method due to temporary assembly as previous clause.

Do procedure above mentioned backward